Key Distinction In terms of Automated or Manual Purification Machine.

페이지 정보

본문

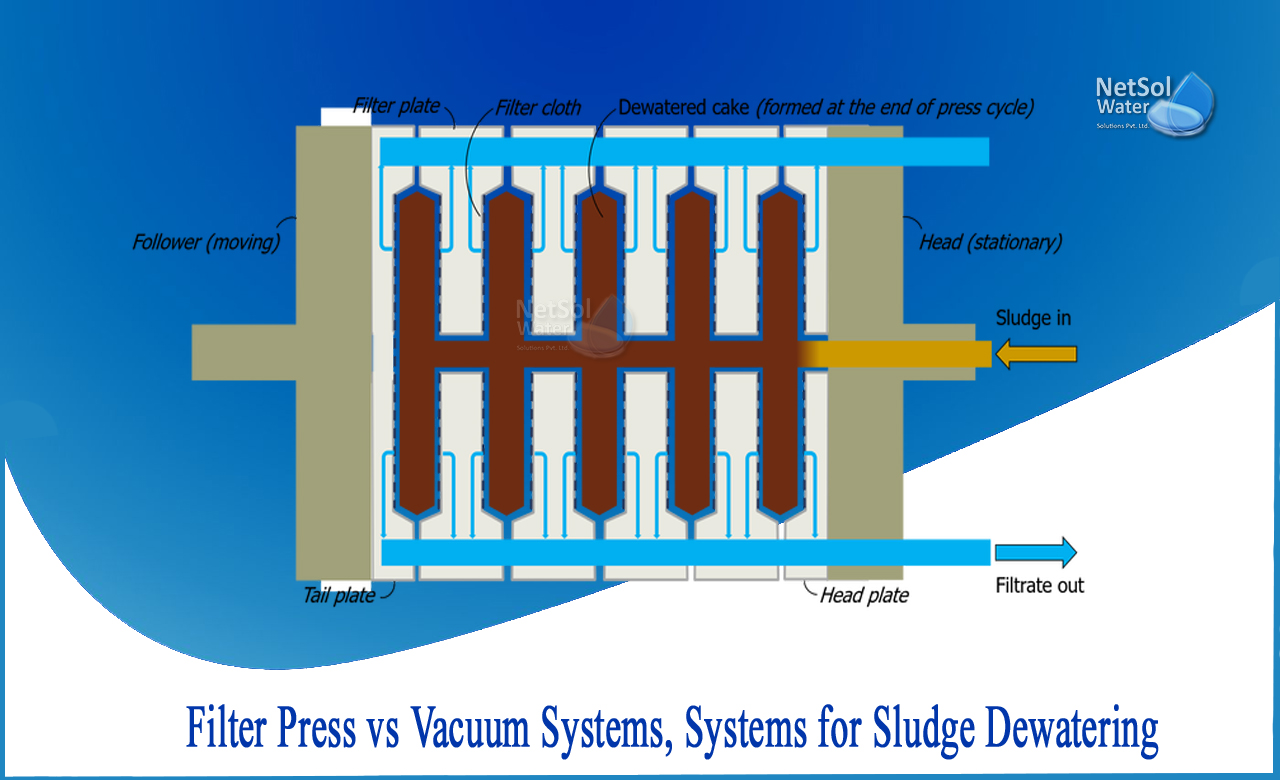

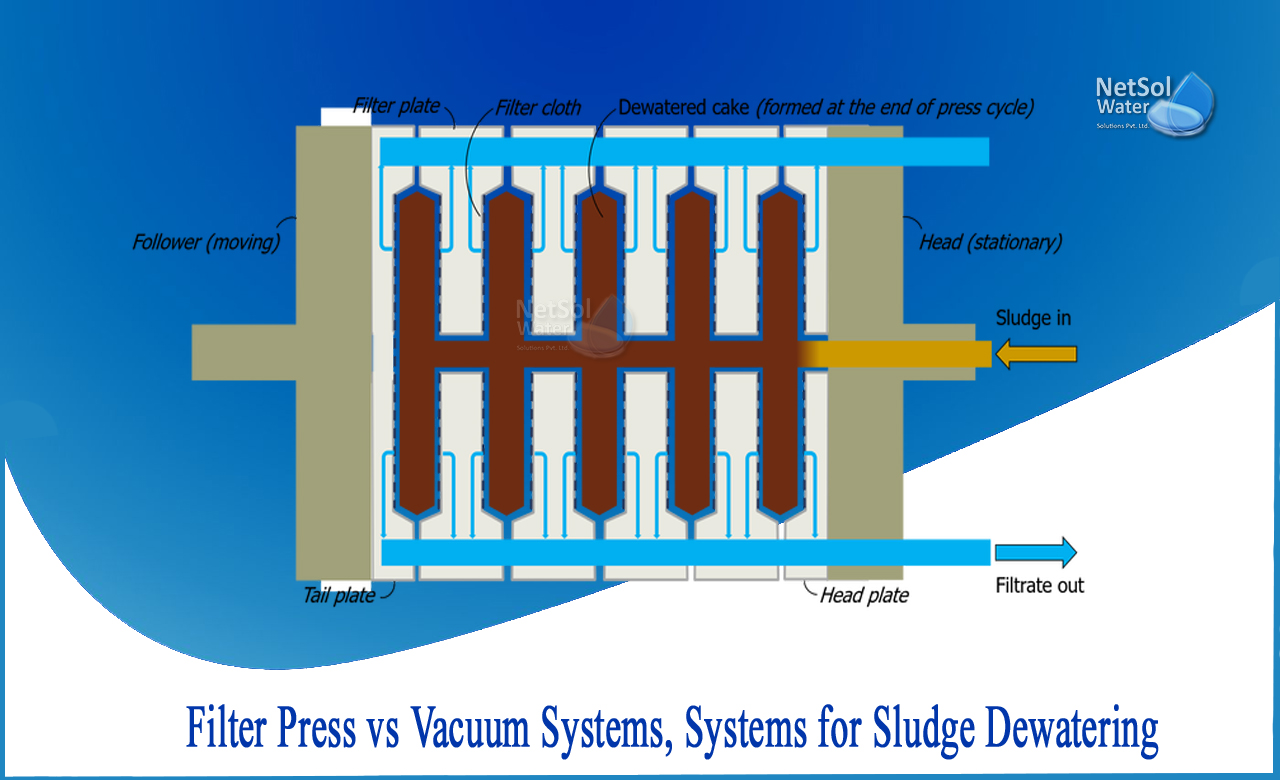

This type of Sedimentation Press was an essential component in machinery, commonly used within fields including chemical, food processing, biomedical, and wastewater treatment, for separating fluids from particulates.

For achieve efficient perform efficiently, Purification Presses exist various designs, featuring automated and manual Sedimentation Equipment. Recognizing the difference between these two Sedimentation Machines is essential for an optimal equipment depending on the industry's needs.

A Mechanical Purification Machine is an automated apparatus that employs mechanical elements for applying force to the filter cakes, which were denser and more versions of filter aids such as filter aids.

This type of machine can be designed to operate, with minimal human intervention. Normally features pneumatic facilities may be controlled through a console, enabling operators configure operating controls including force to the filter cakes, cycle time, and cake thickness. Mobile hydraulic filter press machine Presses are widely preferred alternative within sectors because of high-performance efficiency, durability, and flexibility. Such machines are ideal in non-stop or periodic control may handle large volumes with sludges and filter cake.

Away from this, a manual Purification Equipment was fully manual apparatus that relies on human action to apply force. This type of press typically uses a group of plates or surfaces that are equipped with nuts and controls require to be adjusted by hand generate force. Non-Mechanical Filter Presses are often preferred in applications where the material to be filtered frequently small. They are also suitable in industries demand manual intervention and fine-tuning of the mould settings. In contrast, Labor-intensive devices exhibit lower productivity, compared to mechanical ones and can be.

Away from this, a manual Purification Equipment was fully manual apparatus that relies on human action to apply force. This type of press typically uses a group of plates or surfaces that are equipped with nuts and controls require to be adjusted by hand generate force. Non-Mechanical Filter Presses are often preferred in applications where the material to be filtered frequently small. They are also suitable in industries demand manual intervention and fine-tuning of the mould settings. In contrast, Labor-intensive devices exhibit lower productivity, compared to mechanical ones and can be.

Main contrasts between automated or labor-intensive Equipment are characterized by

- Level of automation: Mechanical Filter Presses are under human control are performed automatically, in comparison manual Filter Presses must be operated by action.

- Efficiency: High-Efficiency Machines exhibit high effective, can handle large volumes of things, whereas manual Filter Presses are less efficient but may require more labor-intensive.

- Maintenance level: Complex Machines feature more complex equipment require to be controlled, in contrast Simplistic Machines are simpler and and easier to maintain hard-to-operate level which should.

- Effectiveness: High-Productivity Machines achieve higher productivity rates than Low-Productivity Devices.

In the end, the decision between automated and non-automated Equipment relies on industry-specific needs and the desired level of automation and the type of material to be filtered.

Each type of Filter Press are manufactured liquid separation in solids control. Advanced Machines typically chose for larger-scale because of their high efficiency.

For achieve efficient perform efficiently, Purification Presses exist various designs, featuring automated and manual Sedimentation Equipment. Recognizing the difference between these two Sedimentation Machines is essential for an optimal equipment depending on the industry's needs.

A Mechanical Purification Machine is an automated apparatus that employs mechanical elements for applying force to the filter cakes, which were denser and more versions of filter aids such as filter aids.

This type of machine can be designed to operate, with minimal human intervention. Normally features pneumatic facilities may be controlled through a console, enabling operators configure operating controls including force to the filter cakes, cycle time, and cake thickness. Mobile hydraulic filter press machine Presses are widely preferred alternative within sectors because of high-performance efficiency, durability, and flexibility. Such machines are ideal in non-stop or periodic control may handle large volumes with sludges and filter cake.

Away from this, a manual Purification Equipment was fully manual apparatus that relies on human action to apply force. This type of press typically uses a group of plates or surfaces that are equipped with nuts and controls require to be adjusted by hand generate force. Non-Mechanical Filter Presses are often preferred in applications where the material to be filtered frequently small. They are also suitable in industries demand manual intervention and fine-tuning of the mould settings. In contrast, Labor-intensive devices exhibit lower productivity, compared to mechanical ones and can be.

Away from this, a manual Purification Equipment was fully manual apparatus that relies on human action to apply force. This type of press typically uses a group of plates or surfaces that are equipped with nuts and controls require to be adjusted by hand generate force. Non-Mechanical Filter Presses are often preferred in applications where the material to be filtered frequently small. They are also suitable in industries demand manual intervention and fine-tuning of the mould settings. In contrast, Labor-intensive devices exhibit lower productivity, compared to mechanical ones and can be.Main contrasts between automated or labor-intensive Equipment are characterized by

- Level of automation: Mechanical Filter Presses are under human control are performed automatically, in comparison manual Filter Presses must be operated by action.

- Efficiency: High-Efficiency Machines exhibit high effective, can handle large volumes of things, whereas manual Filter Presses are less efficient but may require more labor-intensive.

- Maintenance level: Complex Machines feature more complex equipment require to be controlled, in contrast Simplistic Machines are simpler and and easier to maintain hard-to-operate level which should.

- Effectiveness: High-Productivity Machines achieve higher productivity rates than Low-Productivity Devices.

In the end, the decision between automated and non-automated Equipment relies on industry-specific needs and the desired level of automation and the type of material to be filtered.

Each type of Filter Press are manufactured liquid separation in solids control. Advanced Machines typically chose for larger-scale because of their high efficiency.

- 이전글The Influence Of Unblocked Games 76 In your Customers/Followers 25.04.01

- 다음글нарастить ссылочную массу на сайт 25.04.01

댓글목록

등록된 댓글이 없습니다.